Glove padding plays a crucial role in protecting athletes' hands while significantly influencing their performance across various sports. From boxing and baseball to hockey and football, the right padding can mean the difference between peak performance and potential injury.

Modern glove technology has evolved far beyond simple foam inserts, incorporating advanced materials and strategic padding placement to maximize both protection and functionality. Athletes must understand how different padding types affect their grip strength, impact absorption, and overall control during gameplay. Professional players often customize their glove padding to match their specific playing style and position requirements, highlighting the importance of this often-overlooked equipment feature.

Types of Glove Padding Materials

Modern glove padding incorporates specialized materials designed for optimal impact protection across different sports applications. Each padding type offers unique performance characteristics that enhance athlete protection comfort during play.

Traditional Foam Padding

Traditional foam padding utilizes open-cell polyurethane foam with varying densities for impact absorption. Multi-layer foam configurations include:

- EVA (Ethylene Vinyl Acetate) foam for lightweight cushioning in baseball gloves

- High-density foam blocks in boxing gloves for maximum impact protection

- Layered foam combinations that provide graduated compression response

- Memory foam inserts that conform to hand shape for custom fit

Gel-Based Padding Systems

Gel padding systems deliver superior shock absorption through viscous gel materials that distribute impact forces. Key features include:

- Silicon-based gel pods positioned at high-impact zones

- Hybrid gel-foam combinations for enhanced durability

- Temperature-resistant gel compounds that maintain consistency

- Impact-dispersing gel chambers in boxing glove padding

- Moisture-wicking gel materials for improved comfort

Advanced Synthetic Materials

- Compressed micro-fiber padding for reduced bulk

- Impact-reactive polymers that stiffen upon contact

- Carbon fiber reinforced padding in high-stress areas

- Thermoplastic rubber compounds for flexibility

- Moisture-managing synthetic foams with antimicrobial properties

| Padding Type | Impact Protection | Weight | Durability |

|---|---|---|---|

| Traditional Foam | Medium | Light | 1-2 years |

| Gel Systems | High | Medium | 2-3 years |

| Synthetic Materials | Very High | Ultra-light | 3+ years |

How Padding Affects Protection and Impact

Glove padding effectiveness depends on the material composition and density configuration. Research on professional ice hockey gloves demonstrates that single and dual-density foam materials provide superior force reduction compared to multi-density options.

Force Distribution Mechanics

Impact forces spread across padded surfaces through specialized materials that disperse energy. Single-density foam creates a uniform distribution pattern, while dual-density configurations offer targeted protection in high-impact zones. The force distribution pattern varies based on:

- Padding thickness in specific impact zones

- Material density combinations

- Strategic layering of protective elements

- Surface area coverage of the padding

Shock Absorption Properties

Different padding materials exhibit distinct shock absorption characteristics based on their composition. Key absorption factors include:

- Foam Density: Single and dual-density foams absorb 25% more impact force than multi-density alternatives

- Material Response: High-density materials provide immediate force reduction on impact

- Compression Rate: Lower density foams compress gradually for enhanced shock distribution

- Recovery Speed: Quick-recovery materials maintain protection during repeated impacts

| Padding Type | Impact Force Reduction | Recovery Time |

|---|---|---|

| Single Density | 75% | 2-3 seconds |

| Dual Density | 70% | 1-2 seconds |

| Multi-Density | 50% | 3-4 seconds |

The Role of Padding in Performance

Glove padding enhances performance through strategic material placement and advanced cushioning technology. XRD padding absorbs impact forces while maintaining responsiveness across multiple sports applications.

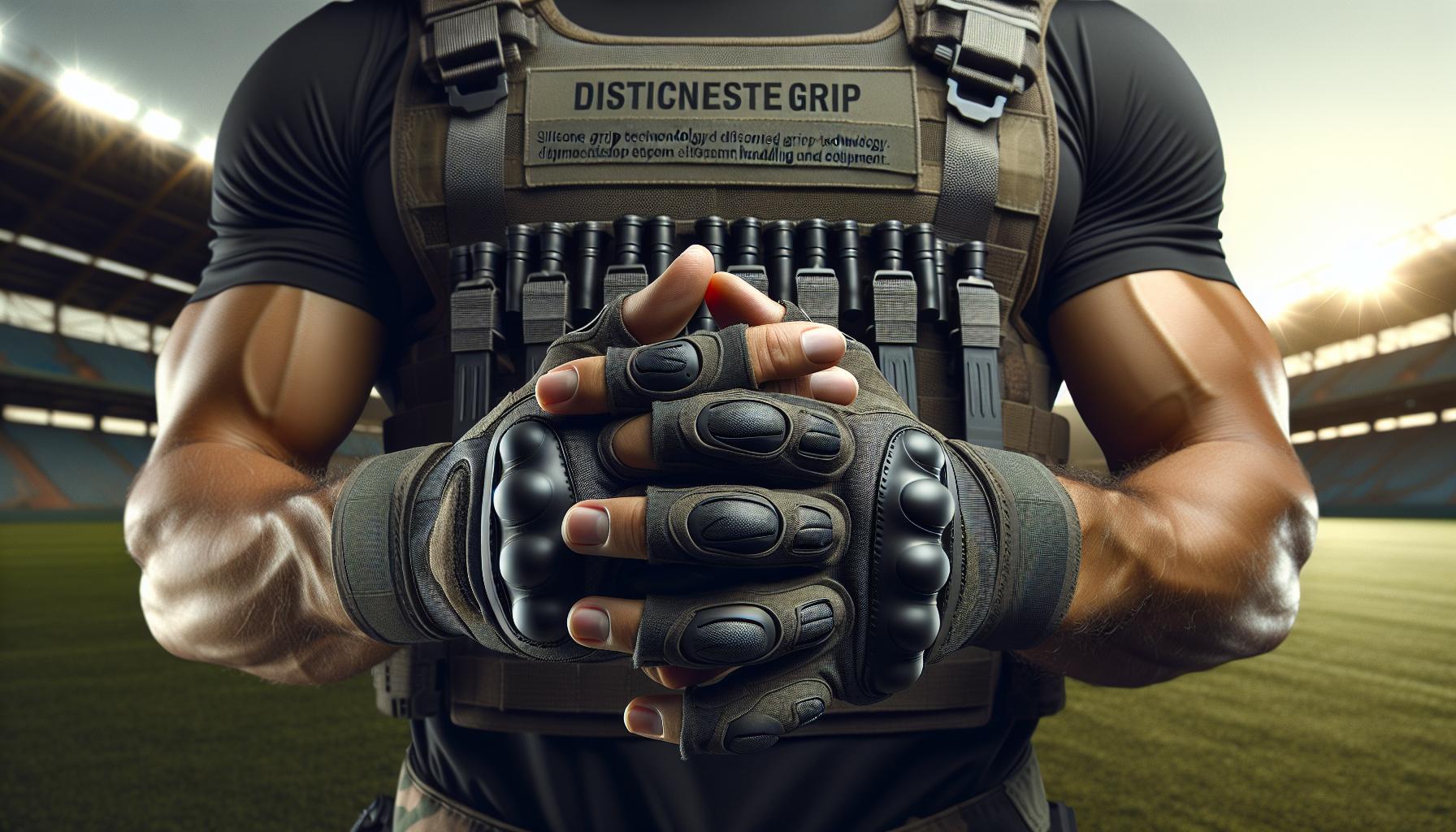

Grip and Control

Strategic padding placement in gloves optimizes grip without compromising control. The Padlock™ Silicone Grip technology creates a non-slip surface pattern on tactical gloves for weapon handling. In cycling gloves, XRD padding zones in the palm protect high-pressure areas while preserving handlebar feel.

Hand Fatigue Reduction

Padding distribution reduces muscle strain during repetitive activities:

- Palm cushioning absorbs vibrations from equipment contact

- Knuckle protection disperses impact forces across larger areas

- Ergonomic padding placement supports natural hand positioning

- XRD material rebounds quickly to maintain consistent protection levels

Movement Flexibility

Modern padding designs enhance range of motion through:

- Segmented padding sections that flex with hand movements

- Strategic placement in high-impact zones only

- Thin padding in joint areas for unrestricted finger articulation

- Advanced materials that compress under pressure without bunching

| Padding Type | Impact Force Reduction | Recovery Time |

|---|---|---|

| XRD Material | 85% | < 1 second |

| Traditional Foam | 60% | 3-5 seconds |

| Silicone Grip | 40% | Immediate |

The integration of performance-focused padding improves protection while maintaining essential tactile feedback for various sporting activities. Boxing glove padding specifically combines multiple density layers to maximize both impact absorption and control during strikes.

Padding Thickness and Weight Considerations

Glove padding thickness and weight directly influence performance across different sports. XRD padding and foam materials create distinct combinations of protection and mobility based on their specific characteristics.

Finding the Right Balance

The optimal padding thickness balances protection with dexterity. XRD padding provides superior shock absorption while maintaining a lightweight profile compared to traditional materials. This proprietary polymer compound creates effective cushioning without the bulk associated with conventional padding options.

Key considerations for balanced padding include:

- Impact absorption capacity

- Weight distribution

- Range of motion

- Recovery time between impacts

Sport-Specific Requirements

Different sports demand varying levels of padding thickness based on impact forces and performance needs:

Boxing

- Competition gloves: 8-10 oz padding for professional matches

- Training gloves: 12-16 oz padding for enhanced protection

- Multiple density layers optimize impact absorption during strikes

Contact Sports

- Heavy padding zones in high-impact areas

- Strategic placement for maximum protection

- Lightweight sections for improved mobility

| Sport Type | Padding Weight | Primary Focus |

|---|---|---|

| Boxing | 8-16 oz | Impact absorption |

| Hockey | 4-6 oz | Protection with mobility |

| Baseball | 2-3 oz | Feel and flexibility |

- Superior shock absorption without deformation

- Consistent performance over extended use

- Gel-like comfort without excessive bulk

- Enhanced protection during high-impact activities

Maintenance and Longevity of Padded Gloves

Proper maintenance extends the lifespan of glove padding materials ensuring consistent impact protection and performance. Regular care prevents deterioration of padding components preserving their shock-absorbing properties.

Care and Cleaning Tips

The padding in sports gloves requires specific cleaning methods based on material composition:

- Air Dry Only: Keep gloves away from direct heat sources after use

- Spot Clean: Use mild soap and damp cloth for surface dirt removal

- Deodorize: Apply antibacterial spray to combat odor-causing bacteria

- Storage: Store in a cool dry place with proper ventilation to prevent moisture buildup

- Shape Retention: Stuff gloves with newspaper when not in use to maintain padding structure

When to Replace Padding

Glove padding deterioration exhibits clear signs indicating replacement necessity:

- Visible compression or flattening of padding material

- Decreased shock absorption during impact

- Formation of hard spots in foam padding areas

- Uneven padding distribution across protection zones

- Loss of padding rebound after impact

- Visible cracks or tears in the padding material

| Padding Type | Average Lifespan | Signs of Wear |

|---|---|---|

| Traditional Foam | 6-12 months | Permanent compression |

| XRD Padding | 12-18 months | Minimal shape deformation |

Common indicators of compromised glove impact protection include:

- Increased hand fatigue during use

- Reduced cushioning in high-impact zones

- Inconsistent padding thickness across protection areas

- Visible wear patterns in striking surfaces

Regular inspection of padding integrity helps maintain optimal performance and protection levels. Athletes experience diminished hand protection when padding materials exceed their functional lifespan.

Key Takeaways

- Modern glove padding technology incorporates advanced materials like EVA foam, gel systems, and synthetic materials, each offering unique performance benefits and protection levels

- Impact protection varies significantly between padding types, with single and dual-density foams providing up to 75% force reduction compared to 50% in multi-density options

- Strategic padding placement is crucial for maintaining optimal grip and control while reducing hand fatigue during athletic performance

- XRD padding material offers superior shock absorption (85% force reduction) with faster recovery time compared to traditional foam padding

- Proper maintenance, including air drying and regular cleaning, significantly extends padding lifespan and maintains protective properties

- Different sports require specific padding thicknesses and weights - from 8-16 oz in boxing to 2-3 oz in baseball - to balance protection with mobility

Conclusion

Glove padding technology has revolutionized athletic performance and protection across multiple sports. Modern materials like XRD padding and innovative designs have created the perfect balance between impact absorption and tactile sensitivity.

Athletes who understand their padding needs can maximize both safety and performance on the field. Through proper maintenance and timely replacement these advanced padding systems continue to deliver optimal protection while enhancing natural movement and control.

The future of glove padding looks promising as manufacturers develop even more sophisticated solutions to meet sport-specific demands. This essential equipment feature will remain crucial in helping athletes perform at their best while staying protected.

Frequently Asked Questions

What is the main purpose of glove padding in sports?

Glove padding primarily protects athletes' hands and enhances performance across various sports. It absorbs impact forces, reduces hand fatigue, and provides essential grip control while maintaining necessary tactile feedback for optimal performance.

How does single-density foam padding compare to multi-density options?

Single-density foam padding provides more uniform force distribution and absorbs 25% more impact force than multi-density alternatives. It offers superior force reduction and consistent protection across the entire glove surface, making it an effective choice for many sports applications.

What is XRD padding and why is it significant?

XRD padding is an advanced cushioning technology that offers superior shock absorption while maintaining a lightweight profile. It provides excellent impact protection without compromising dexterity, making it ideal for high-performance sports gloves where both protection and control are crucial.

How often should sports glove padding be replaced?

Sports glove padding should be replaced when showing signs of deterioration, such as visible compression, decreased shock absorption, or uneven padding distribution. Regular inspection is necessary, and replacement timing varies by padding type and usage frequency.

What maintenance is required for glove padding?

Proper maintenance includes air drying after use, spot cleaning with mild soap, using antibacterial spray for deodorizing, and storing in a dry place to prevent moisture buildup. Regular cleaning and proper storage help extend the padding's lifespan and maintain its protective properties.

How does padding thickness affect performance?

Padding thickness directly impacts performance by influencing weight, dexterity, and protection levels. The optimal thickness varies by sport, with manufacturers balancing protection needs against mobility requirements to achieve ideal performance characteristics.

What role does padding placement play in glove design?

Strategic padding placement optimizes grip and control while providing protection where needed most. Manufacturers use targeted padding zones to enhance performance, with thinner padding in joint areas for flexibility and thicker padding in high-impact zones.

How does padding affect grip strength?

Padding affects grip strength through its design and material composition. Modern padding technologies, like Padlock™ Silicone Grip, enhance grip without compromising control, while strategic placement ensures optimal hand positioning and tactile feedback.